Polycarbonate windows are very practical for a closed gazebo, as they are easy to install and not difficult to care for. In addition, this material can be selected in many specialized stores in shape, size and necessary parameters. The cost of such windows is relatively inexpensive. They have different colors, structure and configurations for every taste.

Glazing options

The glazing process of the gazebo can occur in two versions - solid and partial. His choice depends on the design of the structure. In the first case, glass is usually installed from the floor to the roof, and the second option is mounted on a support in the form of a fence.

Solid

Polycarbonate for continuous glazing is attached to pre-installed structural supports.

When arranging such an arbor, a number of features should be taken into account:

- First you need to make the foundation and foundation, which is most often made columnar. Wooden logs are placed on it. Such columns are laid out of brick, and their height should be 35–40 cm above the ground level.

- The floor is equipped with squared logs. They lay a board and moisture-resistant plywood sheets.

- Support columns are placed vertically, and then fixed with special corners and brackets.

- To avoid strong pressure on the double-glazed windows, lightweight building materials should be used to equip the roof.

- Polycarbonate with continuous glazing quickly loses heat, so you need to provide for the heating and warming of the gazebo in the cold period.

Partial

Pergolas that are used all year round, experts recommend partially glazing. In this case, double-glazed windows are placed on top of a wooden or brick fence. These materials, especially wood, retain heat better. Such a fence can be up to 1.5 meters. Be sure to include insulating materials in the work, close the slots with mounting foam and sealant.

Important! It is better not to use a metal tile, since it will make the roof heavier. If you still decide to use it, then be sure to take care of a reliable upper harness from the beam.

Sliding Window Construction

When glazing the gazebo with polycarbonate, it is necessary to accurately determine the size of the frames and the remaining measurements, according to which it is necessary to calculate the number of leaves and the material consumption. For clarity, you can make drawings. You should also decide on the type of materials - wood or aluminum profile, two-layer or monolithic polycarbonate. The sliding system itself can be designed for a cold or warm room, since with heating it has certain technical features.

According to the principle of action, such systems are divided into:

- lifting and sliding;

- parallel-sliding;

- folding ("accordions").

All systems consist of a supporting and movable frame, and also have running rollers. In some of them, you can use a sliding mosquito net. "Accordion" consists of several wings and is mounted for unheated rooms, because it does not isolate it well. When assembling such windows with your own hands, it is best to buy and assemble ready-made kits for such systems to frames.

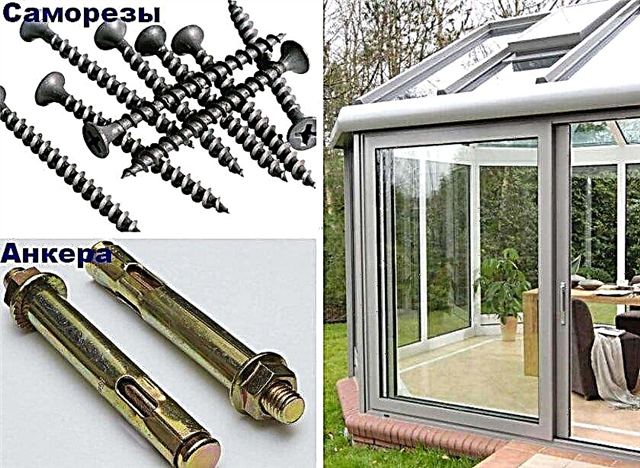

The choice of materials, as well as the sliding system itself, depends on the features of the building, the available means, tools and skills. Many homeowners, for the first time faced with the need to install windows, prefer to take wood for the manufacture of frames.In addition to the material itself for sliding systems, it is necessary to purchase related tools:

- polyurethane foam;

- protective tape;

- sealant (silicone);

- fasteners (anchors, screws and screws);

- washers.

Inventory required for work:

- screwdriver;

- drill;

- hacksaw or jigsaw;

- pencil;

- measuring instruments (tape measure, square, level);

- construction knife;

- circular or hand saw.

Frame and sash assembly

First, a support frame is installed according to the principle of window boxes. Then the web is assembled and a roller system is attached to it. Using a construction knife, polycarbonate is cut according to the markings and inserted into a wooden frame. Cutting can also be done with a circular saw. The ends of the polycarbonate fabric before installation are sealed with a special tape or covered with an end plate, which is fixed with silicone. The frames are inserted into the grooves and nailed with glazing beads, and then sealant is used.

Important! When marking and cutting polycarbonate sheets, it must be taken into account that they must be installed so that the air ducts are located vertically. Otherwise, condensate fluid will clog in them.

Frame Installation Procedure

The wooden carrier box is mounted depending on the existing frame of the gazebo.

You can nail it in two ways:

- screws - to the wooden perimeter;

- anchors - to concrete, stone or brick.

All slots are sealed with foam. In its lower part, with a jigsaw or hacksaw, the guide strips are preliminarily sawn out according to the size of the rollers. After installation, they are attached together with other elements of the sliding system and inserted into ready-made window panels. Seals can also be used at the edges of the sliding window.

Sash installation and adjustment

The position of the flaps is regulated by means of bolts located on the roller mechanisms. If the rollers are not provided, but a simple mechanism is used, then the moving structural elements must move well along the previously cut grooves. Also on the wings you can install a locking mechanism.

Did you know? Primitive sliding doors were used in ancient Rome. Excavations in the city of Pompeii witnessed this.

Advantages and disadvantages of the material

Polycarbonate is now becoming an increasingly popular material.

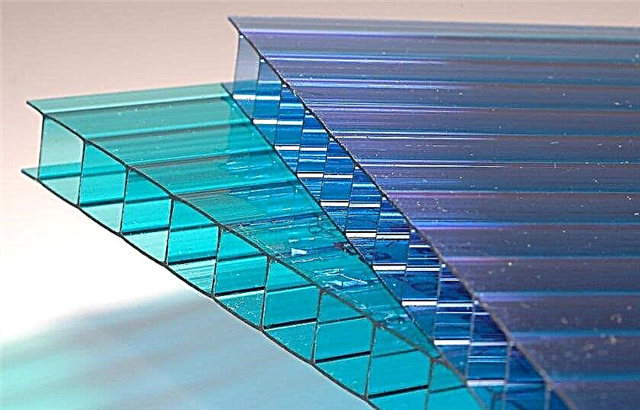

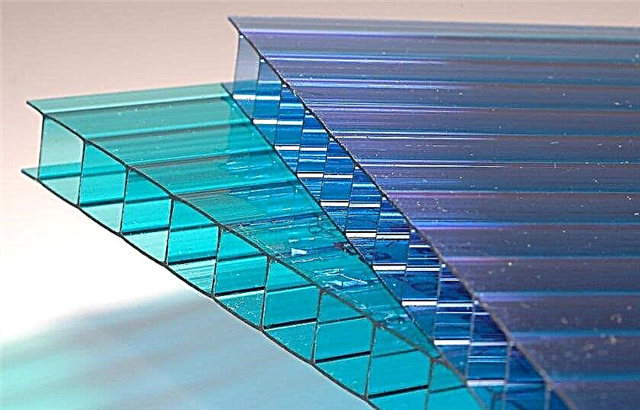

It is of two types:

- Structured. It has inside two or more layers with a large number of jumpers. It has high flexibility, lightness and good insulation properties. Differs in inexpensive cost. Among the disadvantages are a low level of strength, low ability to transmit light.

- Monolithic. Contains no voids and looks like silicate glass. It weighs more than a structured option and costs more. It does not transmit ultraviolet light and is considered stronger. There is even bulletproof monolithic polycarbonate.

Both materials can be inserted into aluminum and plastic profiles, into wooden frames. When installing polycarbonate, it should be borne in mind that it is easily scratched. The material is excellent for building and glazing greenhouses, arbors, terraces and verandas.

- This is due to the following advantages:

- Strength. It can withstand gusts of wind and mechanical stress.

- Light weight. The material does not load the supporting structures and the foundation.

- Inexpensive price.

- Ability to bend. From it you can make arches and a canopy for the gazebo.

- Security. Polycarbonate does not ignite, does not emit harmful substances, does not break into fragments.

- Resistance to temperature extremes and frosts.

- Good heat and sound insulating qualities.

- Stamina to chemical influences.

- The ability to transmit light.

- Resistance to sunlight and ultraviolet radiation.

- Possibilities of tinting.

- Easy installation and repair.

Did you know? Polycarbonate was patented in 1953 almost simultaneously by two specialists from different companies: Hermann Schnell (BAYER, Germany) and Daniel Fox (General Electric, USA).

The summerhouse can be glazed with polycarbonate with your own hands. It is lightweight, affordable, flexible and can be made to order. An excellent option for street buildings is the installation of windows with sliding systems that can be mounted using the same material.