Many summer residents dream of a greenhouse, and it is especially nice if it is built independently - this will save the family budget, and vegetables grown in this design seem much tastier. The main criterion for the construction of a greenhouse or greenhouse is the choice of frame: it must be strong, stable and wear-resistant. The best option is a metal profile frame. Knowing the basic rules of bending a profile pipe, making it with your own hands will not be particularly difficult.

Bending methods

You can bend a profile in many ways. The main thing is to know how to choose the right method of bending for a specific type of pipe. To do this, you need to determine the characteristics of the selected product. First of all, a section. As a rule, for the construction of greenhouses, a metal profile with a rectangular section is used. To bend the pipe without errors, you need to know the height of the profile - h. When the testimony h is less than 20 mm, the bend is carried out on a plot equal to at least h × 2.5. At higher readings, a minimum of h × 3.5 is bent in the area.

Did you know? The profile pipe goes well with polycarbonate not only during the construction of the greenhouse: with this tandem you can build a gazebo, canopy or roof.

You can bend the profile using the hot and cold method, using various devices and machines.

Bending with heating

With profile heights above 40 mm, the craftsmen use the hot method.

Important! It is absolutely impossible to overheat the pipe. If this happens, the workpiece is slightly cooled naturally.

To do this, you must:

- sift medium-grained construction sand, calcine at a temperature of 120–150 ° C;

- make two plugs from wood, on one of them make 4 longitudinal cuts-grooves so that gases are released during the processing;

- a pipe of the required length is plugged on one side with a plug without grooves;

- sand is poured through the funnel, tapping with a wooden or rubber mallet for even distribution throughout the workpiece (a dull sound indicates that the pipe is full);

- the funnel is removed, the profile is clogged with a plug with grooves;

- the place of a bend is marked;

- one side of the metal profile is inserted into a vise, fixed;

- if the pipe is with a welded seam, the profile is fastened with a seam on the side (it is impossible to top or bottom);

- the marked bending spot is heated with a torch or blowtorch to a red-brick color;

- the hot workpiece is bent without sudden movements, smoothly, in one motion, in accordance with the template;

- muscle strength is applied either in the vertical or horizontal plane;

- it is easier to bend using a pipe of a larger diameter, putting it on the free end of the workpiece;

- after cooling, the profile is applied to the template;

- if there are significant errors, the heating and bending procedure is repeated (but still it is recommended to bend from the first, maximum from the second time, otherwise the workpiece will completely deteriorate);

- if everything is in order, knock out or burn out the plugs and pour out the filler.

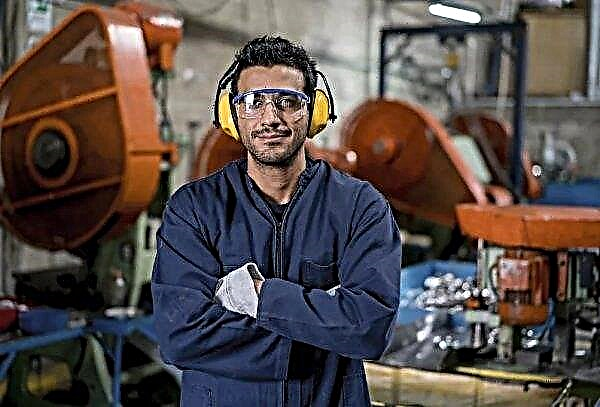

Do not forget about security. You need to work in tight gauntlets

Do not forget about security. You need to work in tight gauntlets

Cold bending

Without heat treatment, you can do-it-yourself bend a metal profile with a height of not more than 40 mm. A pipe up to 10 mm does not need to be filled with anything. If the product has thin walls and a height of more than 10 mm, it must be filled either with sand or rosin.

Another way to cold bend is to fill the pipe with water, followed by freezing. To do this, a plug is placed at one end, the profile is filled with water through the funnel, jammed from the other end and taken out in the cold. After complete solidification, you can begin to bend. With this method, metal rolling is easier to bend, and it does not deform.

Did you know? The area of the largest greenhouse in the world is 22 thousand m². It is located in the UK, and is built of steel tubes with outer panels of thermoplastic.

An alternative to bulk fillers is a tightly wound spring. It is placed inside, after attaching pieces of wire at the ends. The spring should enter freely, but firmly fill the profile pipe.

Machine tools and accessories

The use of various equipment and devices can significantly facilitate and accelerate the work of folding metal profiles. They can be purchased at the store or made independently in your own garage.

Bending by pattern

Template bending is recommended for rolling pipes of small diameter and ductile metals. To do this, a semicircular wooden blank is cut out, attached to a wall or other stable surface. The edge of the profile is fixed on the template. Manually you need to bend the arc around it with an unsecured end.

Manual pipe bender

This is a more complex design. The center of the fixture is a metal semicircular shape (a pipe bends around it). A rack is attached nearby to support the edge of the workpiece. A bearing is placed on the handle. With this simple device, large diameter parts are bent.

Manual or electric machine tools

They are a frame with three steel shafts. On the lower gears are fixed with a chain. They are started using a handle or an electric drive. An edge is mounted on the upper clamping shaft for fixing the part during the rolling process.

DIY pipe bender

With large volumes of bending, it is worth using a pipe bender, but their prices are quite high. You can make it yourself from improvised materials - this will speed up the process, and will not greatly affect the family budget.

Important! At the initial stage of work, an accurate drawing of a pipe bending machine with calculations and proportions should be made.

Materials

For manufacturing you will need:

- the corner is durable;

- channel or plate made of durable metal;

- rollers and roller;

- chain;

- tensioner;

- drive sprockets;

- bearings with housings;

- jack;

- rod for the handle;

- springs for a jack;

- fasteners.

The amount of material depends on the drawing you select. Drive shafts and pressure roller are best ordered from a turner. All other parts do not have to be new.

Most parts for making a home-made profile bending machine can be found in every garage.

Most parts for making a home-made profile bending machine can be found in every garage.

Tools

During the installation process will be used:

- welding machine;

- drill;

- Bulgarian;

- grinding equipment or file;

- drill bits for metal;

- hammer;

- spanners and socket wrenches.

Instruction manual

The drawing is made up, consumables and equipment are prepared - it’s time to assemble the pipe bender:

- Make support rollers and steel pinch roller, conduct the hardening process.

- Place bearings in housings.

- Attach asterisks to the shafts, mark the location of the keyway.

- Drill holes in the limiter nozzles, cut the threads for the clamping bolts.

- In the channel or thick metal plate, drill 2 pairs of holes to secure the bearings. To install a hydraulic jack, they sometimes resort to cutting one of the channel shelves.

- Fasten the pressure roller, weld M8 nuts for the eyes in which the springs will be attached to the base of the pressure roller.

- To make supports and the base of the unit using welding equipment. When mounting the base under the upper roller, it is necessary to achieve absolute evenness with the help of measuring instruments.

- Suspend the platform with the roller on the springs to the top of the bed.

- Drill several rows of holes in the base frame. It is necessary to maintain an accurate distance so that the bearing assemblies do not move, otherwise the perpendicularity of the product will be impaired.

- Install support shafts. Mount the sprockets, the driven and the leading ones, pull the chain.

- At the base of the support frame, cut a notch for the tension roller.

- Install the chain tensioner on the structure and remove the chain slack.

- A handle is made from a rod with a diameter of at least 20 mm to start the machine, a piece of pipe is welded from below the handle, the displacement can be limited by a washer welded to the end.

- The jack is fixed with bolts and nuts on the upper platform of the installation.

After installation is complete, the device must be tested on a small piece of profile.

Video: Homemade pipe bender

The profile for rolling is laid on the lower rollers, pressed with a jack, set in motion with a handle. After the test, the pipe bender is cleaned from corrosion, and the product can also be painted.

Important! Instead of a jack, you can install a helical gear.

A polycarbonate sheet or plastic film is easily attached to a bent metal profile with a rectangular section. Various devices will help to facilitate work. It is possible to minimize defects and damages by knowing the characteristics of the selected profile. Building a greenhouse with your own hands is quite simple if you start work responsibly, armed with the necessary knowledge.