Modern technologies offer a huge variety of useful devices and tools for summer cottages, including those related to greenhouse equipment. According to most experts, polycarbonate is the best material for greenhouse equipment today. Answers to all questions about how to choose and equip such a greenhouse on your site that is included in the kit, which form can be considered the most successful, and also look for many other good tips in this review.

The principle of operation and the arrangement of the greenhouse

Often, inexperienced summer residents, having gathered to equip a greenhouse on their site and hearing that the most reliable, durable, high-quality, in a word, cool greenhouses should be made of cellular polycarbonate, rush to rush to look for a store where there is such a product and begin the buying process with phrases like "advise which is better." As a result, it is highly likely that such a buyer will be sold the most expensive product, which in reality he does not need at all.

In order not to fall into such a trap, you need to spend a little time and figure out what a modern polycarbonate greenhouse is.

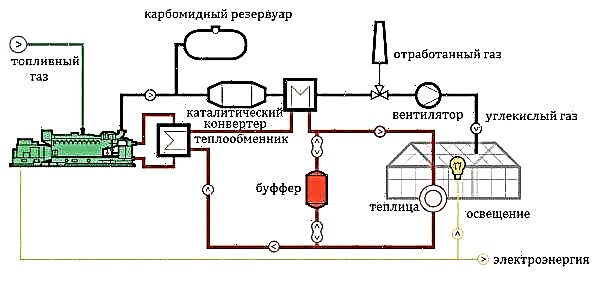

Let's start with physics. A greenhouse is a room whose main purpose is the accumulation of solar light energy, converting it into heat and then storing it as a constant temperature inside, which will allow plants planted there to grow rapidly and actively. In addition, the construction is designed to perform some secondary tasks, in particular, to protect crops from wind, rain and other adverse weather conditions, as well as from various pests.

The process of thermoregulation in the greenhouse is ensured by the principle of accumulation and subsequent return: during the day, the greenhouse heats up and receives heat, cools down at night and releases it. That is why the temperature inside such a room never rises above the permissible limit.

In order to satisfy the stated requirements, the greenhouse, first of all, must be airtight: the less air it passes, the better it will be possible to keep the microclimate necessary for plants in it. Therefore, the thermal conductivity of the material from which its coating is made is of fundamental importance for any greenhouse: the lower this indicator, the better the greenhouse.

However, given the physical processes taking place in the greenhouse, as well as its purpose, the shelter should have other important characteristics, in addition to thermal conductivity.Did you know? Cellular polycarbonate is able to withstand temperatures from -40 to + 130 ° C. These indicators seem unbelievable, however, it turns out that ordinary polyethylene does not lose its properties in the cold from -60 to -269 ° C (depending on type) and begins to melt only at + 60 ° C; in glass, the heat resistance threshold is even higher - from -150 to + 300 ° С.

In particular:

- good light transmission (light should easily pass through the roof and walls, otherwise the whole meaning of the structure is lost);

- ease (modern greenhouses can occupy large areas, heavy weight reduces their stability and increases the requirements for the rigidity of the frame);

- strength and durability (when it comes to stationary structures);

- environmental friendliness (let's not forget that vegetables and fruits, that is, food products, are mainly grown in the shelter);

- adequate cost.

Of all the materials existing today, both natural and artificial, it is best to combine the above-mentioned parameters with a polymer material called polycarbonate.

Nevertheless, polycarbonate has undeniable advantages over its main "competitors" in the manufacture of greenhouses - glass and polyethylene:

- Disadvantages of glass greenhouses:

- lack of flexibility (you cannot give an arched shape);

- fragility;

- high thermal conductivity (cooled in the cold);

- complex installation;

- significant weight;

- high price.

- Disadvantages of greenhouses made of polyethylene:

- low strength;

- instability before gusts of wind;

- inability to achieve high tightness.

Types of Greenhouses

Polycarbonate greenhouses can be classified according to different criteria, but usually, choosing a structure for themselves, the owner of a land plot is primarily interested in its shape. Thanks to the amazing properties of the polymer, it allows you to create the most diverse options for greenhouses - arched, conical, round, rectangular, polygonal and even wall-mounted. Consider some of the most common varieties.

Arched

This type of greenhouse assumes the presence of a sloping roof, made in the form of a semicircle (arch).

This design has several important advantages, among which are worth mentioning:

- increased strength due to the absence of the formation of a heavy snowdrift on the roof (on a curved surface, precipitation does not linger and falls along the walls or flows to the ground);

- good aerodynamic properties (due to the lack of angles, the structure resists wind gusts better);

- durability (the fewer joints, the higher the life of the structure);

- lack of special difficulties during installation;

- lower material consumption (instead of two sheets joined together, there is only one on the roof).

Important! One of the unusual varieties of arched greenhouses is the so-called “butterfly” - a small structure with folding side flaps that provide easy access to plants without having to wade inside the greenhouse. Another interesting option is the so-called "sesame" with a roof consisting of two arcs joined together, which can be moved apart to different widths.

However, it should be noted that arched structures are most often used for growing undersized plants on one horizontal tier, since the optimal height of their walls, which does not require the installation of additional fortifications, cannot exceed 200 cm.

Rectangular

Strictly speaking, in the form of a parallelepiped, greenhouses are usually not satisfied, since a wide and flat roof has every chance of collapsing in winter due to the weight of snow accumulated on it, therefore, rectangular greenhouses usually mean buildings in the form of a house with a gable or gable roof.

Comparing the advantages of one species over another, the following points can be noted:

- Advantages of a shed roof:

- fewer joints (material savings, increased strength, better tightness).

- Advantages of a gable roof:

- better light penetration;

- no risk of errors in calculating the angle of inclination (it is important for determining the strength of resistance to snow accumulation).

The pluses of both types of structures include the absence of difficulties with their assembly, a convenient ventilation system and the ability to select any wall height, which makes such structures more universal.

Polygonal

This type of construction also looks like a house, but instead of a rectangular base and one or two roof slabs, in this case another additional tier is used between the wall and the roof, as if smoothing the joint angle between them. It should be noted that there are more shortcomings in this form than advantages, although it also has its fans.

Preferring a polygonal design, the following important points should be considered:

- Advantages of the polygonal shape:

- very beautiful appearance;

- excellent light transmission;

- good aerodynamic properties.

- Disadvantages of the polygonal shape:

- mandatory production of a drawing;

- assembly difficulties;

- complex ventilation system;

- a large number of additional joints (affects durability, strength and tightness).

Wall

Such greenhouses can have a sloping (semi-arched) or straight (single-pitch) roof, but their main feature is that with one side of the structure the structure is adjacent to the wall of a residential building.

Did you know? The founder of the greenhouse in the modern sense of the word is considered the famous German scientist, philosopher and scholastic, a knight of the Order of Brothers Preachers Albert Magnus, nee Albert Bolshtgedt, who created the first flower greenhouse with a winter garden in Cologne. As usual, the Holy Inquisition did not appreciate the discovery and forbade the construction of greenhouses, and declared Magnus himself a sorcerer who dared to encroach on the established change of seasons.

Such a solution is not without wit, it is extremely convenient in small personal plots and has a number of obvious advantages, in particular:

- rational use of space;

- Significant savings in material and installation time (especially if the laying of the greenhouse occurs simultaneously with the construction of the house);

- additional heating (this is especially important in winter, when the building receives heat directly from the heated house).

How to choose the best greenhouse

Unlike light film shelters that protect the bed from unexpected cooling in the spring and intense heat in the summer, polycarbonate greenhouses are rather massive stationary structures that will serve for more than one year. The numerous and indisputable advantages of such structures determine their rather high cost, and therefore it is necessary to approach the buying process with all responsibility.

Frame material

Perhaps the most important point that you need to pay attention to when choosing a greenhouse is the quality of the frame, because it is he who will take on the burden of snow falling in winter, withstand sharp gusts of wind and other natural disasters.

Important! Polycarbonate is not designed to withstand heavy loads, so the rigidity of the greenhouse made from it provides the frame.

At the beginning of the era of manufacturing greenhouse structures made of polycarbonate, manufacturers used frames from ordinary flat metal ribbons, at best a corner, as a result of which, after the first winter, such structures were often destroyed. Today, a profile with a square section is unambiguously considered the most acceptable option, and frames with a wall thickness of at least 1.2 mm are really strong and reliable.

As for the specific material, the profile can be made of:

- ordinary metal (stainless, low alloy, carbon steel);

- galvanized steel;

- aluminum (plain or anodized);

- plastic (polyvinyl chloride, polypropylene).

Less often, but still there is a use for the manufacture of a frame of wooden bars.

Each of the mentioned materials has its advantages and disadvantages that must be taken into account. For example, aluminum, with similar strength indicators, is much less susceptible to corrosion than any steel, however, the price of such a product will be much higher. A tree, on the contrary, will cost much less, but will not last long.

Covering material

There is little choice. Polycarbonate can be monolithic and cellular, but for greenhouses the second option is almost always used, since it passes heat very poorly, that is, it has high thermal insulation.

An additional advantage of cellular thermoplastic is that, due to its hollow structure, it has a lower specific gravity, which, in turn, reduces the load on the frame and allows the construction of greenhouses of a sufficiently large area.

Important! With the same chemical composition, cellular polycarbonate is at least ten times lighter than monolithic.

Nevertheless, it must be understood that the quality of the material largely depends on the conscientiousness of the manufacturer, in particular, on what raw materials he uses and how strictly he adheres to GOST and other technological standards in his work.

You should also know that for the manufacture of greenhouses polycarbonate panels of different thicknesses are used.

The minimum allowable indicator of this parameter should be 4 mm, but the maximum (6, 8, 10, or even 16 mm) depends on factors such as:

- dimensions, shape and construction of the structure (crate pitch, ramp angle, etc.);

- climatic conditions (wind strength, snow cover thickness, etc.);

- crops to be cultivated.

For example, in cold regions, the bending radius should be maximum so that snow does not linger on the roof, while material 4 mm thick is used for the walls, more durable sheets (6-10 mm) are used for the roof. For growing seedlings, the wall thickness should be at least 6 mm, while early seasonal vegetables can be content with shelter of a minimum thickness.

Another important parameter is color. Since greenhouses are not created for beauty, their quality characteristics must correspond to the needs of plants, and therefore, maximize the conditions of their maintenance to natural. The light transmission of the material should therefore be maximum, and it is provided only by fully transparent panels, while, for example, fashionable bronze color retains at least 60% of the radiation (with an acceptable rate of 20%).

Did you know? In Russia, fashion for greenhouses came during the reign of Tsar Reformer Peter the Great. So, by his decree, a Pharmaceutical Garden was built in St. Petersburg for the cultivation of medicinal plants, including those brought from exotic countries, which had to be specially protected in the harsh winters of St. Petersburg.

Finally, some manufacturers practice applying to the outer (and sometimes inner) layer of a polycarbonate panel a layer of a special material that protects the material from destruction under the influence of ultraviolet rays. The importance of such an option can hardly be overestimated, but since it directly affects the cost of the product, it is enough to opt for polycarbonate with a one-sided protective coating, as well as focus on the products of companies with a good reputation, otherwise expensive material can easily fail the very first strength test .

Size and equipment

The size of any greenhouse, as you know, consists of three parameters - length, width and height, and each of them is important. Of course, when choosing a model, you should first proceed from the area of your own land.

However, in addition to this, some other considerations must be taken into account:

| Length |

|

| Width | The minimum permissible indicator is 2.4 m, the optimal indicator is 3 m (calculated based on the generally accepted width of the racks and the necessary passage between them). |

| Height | It acquires fundamental importance only when using a greenhouse to grow trees or other tall crops. For comfortable operation, this parameter should be at least 1.8 m, although standard models usually provide a two-meter height. |

When choosing a finished greenhouse, it is also important to know what should be included in the package so that the structure can be easily mounted on its own site.

In addition to the polymer sheets themselves of a certain length, as well as the frame, the manufacturer must ensure that the kit contains:Did you know? The largest greenhouse in the world was built in the county of Cornwall, UK, and was called the Eden Project (in a free translation - a paradise project). The construction, consisting of many interconnected domes, covers an area of approximately 22 thousand square kilometers!

- thermal washers and self-tapping screws for mounting sheets;

- end profile to protect the sheet from dirt;

- connecting profiles (not always included in the kit, but they are needed for winter greenhouses made of thick polymer);

- gaskets;

- handles for doors and window leaves;

- hinges for doors and window leaves.

Top greenhouse manufacturers

Polycarbonate greenhouses, made under various brands - Russian, European, Asian, are presented on the domestic market today. Composing a rating of goods with the highest characteristics, including such an important parameter as the ratio of price and quality, at the first steps you can put the products of the following manufacturers:

| Name of manufacturer | Country | Main advantages |

| "Markolon" | Germany |

|

| "Politec" | Switzerland |

|

| Polygal | Israel |

|

| Novattro | Russia |

|

| "Sunnex" | Russia |

|

In addition, a factory producing products under a well-known European brand may physically be located in a third world country, because the actual quality of goods of the same brand can vary from very high to very average.

Important! When choosing a polycarbonate manufacturer, it should be borne in mind that sometimes the technical characteristics and, accordingly, the quality of the goods are determined not by GOST, but by the seller himself (the so-called “Private label” practice, most often used by the Chinese, but recently penetrated the Russian market).

Tips from experienced gardeners

In order not to make a mistake with the choice of a greenhouse, experienced gardeners are advised to be guided by the following rules:

- Always require documents. The quality of polycarbonate should be confirmed by a certificate of an established standard, and not by the sworn assurances of a sales consultant.

- Trust your eyes. The plastic must be completely transparent, without any impurities, opacities, coloring components, as well as scratches, dents and other damage.

- Pay attention to packaging integrity.. A self-respecting manufacturer wraps each sheet of polymer with a protective film with its own logo.

- Check for markings. All material specifications must be indicated on the packaging. It is important that this information includes data on the dimensions (length, width, thickness) of the sheet, the presence of UV protection, the manufacturer.

- To control the technical characteristics of the polymer and the frame, as well as the step of the crate. The minimum allowable polycarbonate thickness is 4 mm, the profile is 1.2 mm. It is better to choose the maximum cross section - 20 x 40 mm, the distance between the frame elements - no more than 70 cm (but not 200 cm).

A polycarbonate greenhouse is the best you can think of to optimize garden work, create the perfect microclimate in the garden and, as a result, get the maximum yield. According to most characteristics, this material outperforms glass and plastic film: it is lightweight, durable, aesthetic and eco-friendly. All that is required of the gardener is to carefully analyze their needs and financial capabilities, choose the right design for yourself among the huge variety of options on the market.

A polycarbonate greenhouse is the best you can think of to optimize garden work, create the perfect microclimate in the garden and, as a result, get the maximum yield. According to most characteristics, this material outperforms glass and plastic film: it is lightweight, durable, aesthetic and eco-friendly. All that is required of the gardener is to carefully analyze their needs and financial capabilities, choose the right design for yourself among the huge variety of options on the market.